36. What requirements should be fulfilled for laying cables?

Answer: The following requirements should be met:

(1) In terms of safe operation, all kinds of external damage should be avoided as much as possible, and the reliability of power supply for the cable line should be improved;

(2) In terms of economy, consider from the perspective of the most investment;

(3) For construction, the route of the cable line must be easy for maintenance after rotation and maintenance.

37. What are the insulation materials for making cable terminations or intermediate joints?

Answer: There are insulating adhesives, insulating tapes, insulating tubes, insulating gloves, and insulating resins.

38, a brief description of the general operation of the cable head production process.

Answer: (1) Preparation before production: Including ○1 reading installation instructions; ○2 viewing site; ○3 stock preparation; ○4 cable trial tide; ○5 pre-production testing.

(2) Manufacturing process of joints: Including ○1 to cut off excess cable; ○2 Stripping of cable protective layer; ○3 Conductor connection; ○4 Winding insulation (or shrinking pipe); ○5 Installation of joint housing; ○6 Perfusion insulation Agent; ○ 7 sealing treatment.

(3) Post-production electrical testing.

39, cable protection tube processing should meet the requirements?

Answer: (1) The nozzle should be sharp and sharp, and the nozzle should be made into a trumpet shape.

(2) After the cable pipe is bent, there shall be no cracks and significant indentations. The degree of bending shall not be greater than 10% of the outside diameter of the pipe; the bending radius of the cable pipe shall not be less than the minimum allowable bending radius of the cable penetrated. .

(3) The metal pipe shall be painted with anticorrosive paint or leaching on the exterior, and the galvanized pipe shall be painted with anticorrosive paint on the zinc layer.

40, the cable arrangement meets what requirements?

Answer: (1) Power cables and control cables should not be placed on the same floor support.

(2) For high and low voltage cables, the strong and weak electric control cables should be arranged in layers in order, and the general situation should be from top to bottom. However, when a high voltage cable with more than 35kv is introduced into the panel, the bend radius can be met by the following Configuration.

41. What is the method of laying cables in cable trenches?

Answer: The method of laying cables in cable trenches is similar to that of buried cables. In general, the pulleys can be placed in the trenches. After the application is completed, the cables are placed on the bottom of the trenches or brackets, and cable labels are tied on the cables.

42. What are the common equipment for laying cables?

Answer: (1) The air compressor is mainly used to damage the road surface and prepare for the laying of cables in the future;

(2) Electric winches or cable haulers, mainly used to pull cables;

(3) The cable conveyor is used with a traction machine to overcome the huge friction and reduce the damage to the cable;

(4) cable tray payout bracket;

(5) Roller device;

(6) Anti-mite, reduce the distortion of the wire rope;

(7) cable disc brake device;

(8) Tensiometer.

43. What are the requirements for the installation distance of brackets in cable trenches?

A: The cable is fixed on the wall of the cable trench and the tunnel. When the horizontal device is installed, when the outer diameter of the cable is equal to or less than 50mm, one support shall be added every 1m; the cable with an outer diameter greater than 50mm shall be added every 0.6m to support; The triangular single cable is fastened with a strap every 1m. When it is vertical, it is fixed every 1~1.5m.

44. How to handle the installation of power cables and control cables in the same bracket?

A: The power cables and control cables should not be laid in the same bracket. When there are few cables and the control cables and power cables are laid in the same bracket, separate partitions are used.

45. How to install a grounding cable in a cable tunnel?

Answer: The whole length of the tunnel and ditch should be installed with a continuous grounding wire. The grounding wire should be connected to all the supports, and the two ends should be connected to the grounding electrode. The specifications of the ground wire should meet the design requirements. In addition to insulation requirements, cable lead packages and armored equipment shall all be connected to each other and to the grounding cable. The cable racks and grounding cables shall be painted with antirust paint or galvanized.

46. What are the requirements for fire blocking of cable holes?

A: For larger cable penetration holes, such as cables running through the floor, when using fire blocking materials to block, according to the actual situation, should be painted on the surface of the cable four to six layers of fire retardant coating, the length of about 1.5m below the hole, and then Refractory materials are used to process the fireproof plugging material with certain strength. It is guaranteed to be solid after plugging and easy to replace and disassemble when replacing the cable. The plugging is dense and non-porous to effectively block the fire and block fire.

47, torch torch before ignition should pay attention to what inspection?

Answer: The following items should be checked:

(1) Whether the pump is leaking oil or leaking oil, leaking oil or gas at the oil barrel or nozzle;

(2) Whether the amount of oil in the drum exceeds 3/4 of the capacity of the drum, and if the screw plug for refueling is tightened.

48. What should be noted when using torches?

Answer: (1) The maximum fuel injection volume of the torch is 3/4 of the volume of the oil cylinder;

(2) The starting pressure should not be too large. After the ignition, the flame can be used from yellow to blue;

(3) There must be no flammable materials around and the air must circulate;

(4) Turn off the adjustment switch when it is deactivated. After the fire is extinguished, slowly loosen the oil hole cover and let go of air. After the air is released, it is necessary to loosen the adjustment switch, and then completely cool and then loosen the hole cover;

(5) Kerosene burners and gasoline burners should be used separately.

49, What is the use of manual hydraulic clamp and how to operate it?

A: The connection of two wires is usually done by inserting two wire ends into a pressure tube made of the same material. Several pits are pressed with crimping pliers to connect the wires together. When the handle is lifted up during crimping, The plunger moves outwards, creating a vacuum in the lower chamber of the oil valve, and the oil in the fuel tank enters the plunger chamber. When the handle is pressed down, the plunger moves inward. After the oil is pressurized, the oil inlet valve is closed, the oil outlet valve is opened, the oil pressure enters the hydraulic cylinder, the piston and the male mold are pushed, and a pressure pipe is placed between the male and female molds. When the crimped crater is deep enough to reach a certain value, the oil return valve is opened and the piston automatically returns. After pressing a pit, the pressure pliers are moved and then pressed down.

50, commonly used low-voltage power cables according to the different insulation and protection layer, which can be divided into several categories?

Answer: (1) Oil-impregnated paper insulated lead (or aluminum) power cable;

(2) Non-dripping oil-impregnated paper-insulated power cables;

(3) PVC insulated PVC sheathed power cable;

(4) cross-linked PVC insulated polyethylene sheathed power cable;

(5) cross-linked PVC insulated PVC sheathed power cable;

(6) Rubber insulated power cable.

51, what are the categories of commonly used insulation materials?

Answer: (1) inorganic insulating materials: mica, asbestos, marble, porcelain, glass, etc.;

(2) Organic insulating materials: resin, rubber, paper, hemp, cotton yarn, etc.;

(3) Mixed insulating materials: Insulating materials of the type that are formed by the above insulating materials.

52. In what kind of situation are the pipes laid? What are the advantages?

A: The laying of pipes is generally used where they intersect with other buildings, roads or railways, and is sometimes used in areas where buildings are dense. The main advantage is that it occupies less space and can withstand large loads. The cables do not affect each other and are relatively safe.

53. What is the long-term allowable ampacity of the cable?

Answer: The long-term allowable ampacity of the cable refers to the current value when the cable conductor reaches the long-term allowable operating temperature after the heat is stabilized in the cable through the specified current.

54. What are the factors that determine the long-term allowable ampacity of the cable?

A: There are three factors that determine:

(1) The long-term allowable operating temperature of the cable;

(2) The thermal performance of the cable itself;

(3) Condition of the cable device and the heat dissipation conditions of the surrounding environment.

55, there are several ways to lay the cable?

A: There are the following types:

(1) buried directly underground;

(2) installed in the cable trench;

(3) Installed in an underground tunnel;

(4) Installed on the interior wall or ceiling of a building;

(5) Installed on the bridge;

(6) laying in the pipe;

(7) Laid under water.

56, how to connect the cable pipe work?

Answer: When the cable pipe is connected, it must be connected with the buckle and the pipe joint. If welding is adopted, direct butt welding is not allowed. The joint should be covered with a thick pipe and then welded so as to prevent the welding slag from falling into the pipe.

57, when making cable heads, what are the requirements for twisting the cable cores up and down?

Answer: When pulling the core, the paper insulation must not be damaged. The bending radius of the core wire must not be less than 10 times that of the cable core. Special care must be taken in the production, so that the bent part of the core should be evenly subjected to force, otherwise the insulating paper can be easily damaged.

58, a brief description of the plastic cable heat shrink seal method.

A: The heat shrink method is applicable to the sealing of middle and low pressure rubber and plastic cable joints and terminal heads. It can also be applied to non-dripping and viscous impregnated insulated cables. The cross-linked polyethylene type and silicone rubber type heat shrinkable tube that can be uniformly shrunk when heated. The tube is placed over a predetermined adhesive seal, and a hot melt adhesive is applied to the adhesive site. When heated to a certain temperature, the heat shrinkable tube shrinks, and the hot melt adhesive melts. After being naturally cooled, the tube is formed. Good seal seal.

59. What should you pay attention to when bending a cable protection tube with an electric bending machine?

Answer: (1) The bender should be operated by a person who understands its performance and is familiar with the operating knowledge.

(2) Inspection must be performed before use. Buttons, operating handles, and travel switches should be in good condition. The bender must be reliably grounded.

(3) Choose the mold that meets the requirements and determine the required bending radius;

(4) There should be sufficient activity range around the construction site;

(5) When the idling is normal after use, it can work with load. In operation, it is forbidden to touch the rotating part with hands and feet;

(6) Power outage should be promptly completed after work is completed to release oil pressure.

The production cable can be divided into more than 50 varieties and subdivided into 1000 specifications.All products have passed national certification, such as China compulsory certification, bv certification, Nigerian SONCAP certificate, China national industrial certification, etc. China national industrial production license, etc.It also has the ability to produce products that meet international standards, such as iec, ce, rohs, etc.

If you want to buy wires and cables, you can ask the customer service staff and we will get back to you as soon as possible.

-

600-1000V CU XLPE Power Cable

Conductor:Bare Copper Conductor of Class 1/2 (Solid)

Insulation:XLPE Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request

-

600-1000V AL XLPE Power Cable

3500 V:Bare Aluminum Conductor of Class 1/2 (Solid)

Insulation:XLPE Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request

-

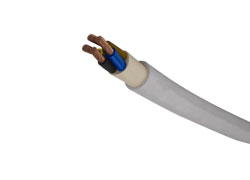

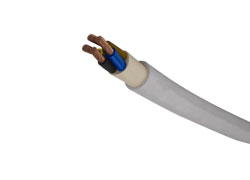

600-1000V Flexible Power Cable

Conductor:Bare Copper Conductor of Class 5 (Flexible)

Insulation:PVC Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request

-

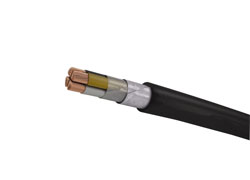

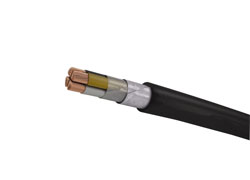

600-1000V SWA Armoured Cable

Conductor:Bare Copper Conductor of Class 1/2 (Solid)

Insulation:XLPE Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request