60. What is the meaning of cable inventory and cable number?

Answer: The cable inventory is the basis for laying out the cable and guiding the construction, operation and maintenance of the file information. Should be included in each cable number, starting point, model, size, length, and statistics of the total length of the classification, control cable should also list the spare core of each cable.

The cable number is a sign of the identification cable, so the whole plant number is not repeated, and there are certain meanings and laws that can express the characteristics of the cable.

61. The current laying methods of cables can be divided into several categories.

A: (1) Artificially laid, that is, employing human-sea tactics, under the coordination and command of one or more people, laying according to regulations;

(2) mechanized laying, that is, the use of rollers, tractors, conveyors, through a synchronous power control, more secure;

(3) The combination of labor and machinery, some sites due to more turns, construction is difficult, full use of machinery is more difficult, so use this method.

62, what requirements should be met to control the secondary circuit wiring?

Answer: (1) According to the figure, the wiring is correct;

(2) The electrical connection of the wire should be solid and reliable;

(3) The wires in the cabinet shall not have joints, and the core wires shall be free of damage;

(4) The end of the cable core should be marked with the loop number, the number should be correct, the writing is clear and it is not easy to decolorize;

(5) The wiring shall be neat, clear and beautiful, and the insulation of the conductor shall be good and non-destructive;

(6) The wiring on each side of each terminal should be one wire, and the maximum number of wires must not exceed two.

63, what are the requirements of the cable pipe?

Answer: (1) The distance from the top of the pipe to the ground is 0.2m in the factory, 0.5m under the sidewalk, and 0.7m in the general area;

(2) Well pits shall be installed in the direction of change and at the branches, and pits shall also be provided when the length exceeds 30mm;

(3) The depth of the pit is not less than 0.8m, and the diameter of the manhole is not less than 0.7mm;

(4) The drainage pipe should have a slope gradient of 0.5% to 1% in the pit.

64, what are the requirements for the resistance of the cable conductor connection point?

Answer: It is required that the resistance of the connection point is small and stable, and the ratio of the resistance of the connection point to the conductor of the same length and the same cross-section should not be greater than 1 for newly installed terminal heads and intermediate terminals; for the terminal heads and intermediate heads in operation This ratio should not exceed 1.2.

65, cable connector and the middle of the design should meet what requirements?

Answer: The requirements that should be met are:

(1) high pressure strength, good conductor connection;

(2) Large mechanical strength and small medium loss;

(3) Simple structure and strong sealing.

66. What is a cable fault? There are several common types?

Answer: The cable fault refers to the breakdown of the cable line due to the breakdown of the cable during the preventive test or the operation of the cable due to the breakdown of the cable or the blow of the cable. Common faults include ground faults, short-circuit faults, breakage faults, flashover faults, and hybrid faults.

67, how to deal with single-phase earth fault cable line?

A: Single-phase earth fault of cable line In general, the damage of the cable conductor is only partial. If it is a mechanical damage and the soil near the fault point is relatively dry, partial repairs are usually performed and a false joint is added. Do not cut the cable core, only the insulation of the fault point can be sealed.

68. What tests and inspections should be conducted before the power cable is laid?

Answer: Before laying, check whether the cable's type, size and length are in compliance with the requirements. Is there any external damage? The low-voltage cable uses a 1000V megohmmeter to measure the insulation resistance. The resistance is generally not less than 10MΩ. The high-voltage cable is measured with a 2500V megohmmeter. The resistance generally does not reach 400MΩ.

69. What should you pay attention to when laying cables in the main building?

A: When laying cables in the main building, you should generally pay attention to:

(1) All control cables leading to the central control room shall be laid overhead;

(2) 6KV cables are to be laid by tunnels or pipes, and the groundwater level may be elevated or laid by cascading pipes;

(3) 380V cables When both ends of the cable are at zero meters, tunnels, gutters, or pipes should be used. When one end of the equipment is at the upper end and the other is at the lower end, it can be partially laid overhead. When the groundwater level is high, it should be overhead.

70. What is the location of the inner and outer shields of the power cable? What material is used and what is the role?

Answer: In order to make the insulation layer and the cable conductor have better contact and eliminate the increase of the electric field strength on the surface of the conductor caused by the non-smooth surface of the conductor, the inner shield layer of metalized paper or semiconductor paper tape is generally covered on the conductor surface. In order to make the insulating layer and the metal sheath have better contact, generally the outer layer of the insulating layer is covered with an outer shield layer. The material of the outer screen layer and the inner screen layer are the same, and sometimes the copper tape or the braided copper ribbon is also used.

71. Briefly describe the composition and properties of epoxy resin composites.

A: Epoxy resin composites consist of epoxy resin, hardener, filler flexibilizer, and thinner. Has the following properties:

(1) Have sufficient mechanical strength;

(2) Excellent electrical performance;

(3) Stable electrical performance;

(4) Adequate adhesion with non-ferrous metals;

(5) good corrosion resistance;

(6) It is resistant to rain, light and moisture when it is used outdoors.

72. Why should a single-core cable sheath grounded in one end be installed with a reflow line laid along the cable?

Answer: In the cable line grounded at one end of the metal sheath, in order to ensure that the induced voltage in the sheath does not exceed the allowable standard, a conductor laid in parallel along the cable line must be installed, and both ends of the conductor are grounded. This conductor is called back Streamline. When a single-phase ground fault occurs, the ground short-circuit current can flow back to the center of the system through the return line, and the magnetic flux generated by the ground current through the return line cancels the magnetic flux generated by the ground current of a part of the cable conductor and can be reduced. The induced voltage of the sheath in the event of a short circuit.

73, cable engineering can be divided into several projects?

A: (1) Site transportation: including the loading, unloading and transportation of engineering materials from the warehouse to the construction site and return of empty vehicles.

(2) Local projects: including road excavation, tunnels, and trench construction.

(3) Laying project: including laying, intermediate head making, flipping cover plate, buried pipe, school tide, traction head making and so on.

(4) Both ends of the project: including the production and installation of supports, suspension bridges and their foundations, the production of terminal heads, the installation of oil pressure and signal devices, and the testing of electrical properties.

(5) Plug and stop project: including the production of oil-filled cable plugs and heads, installation of fuel tanks, automatic drainage and signal devices, etc.

(6) Grounding: Including insulation joints, transposition boxes, protectors, and grounding box installation.

74. What inspections should be performed on the acceptance of cable lines?

Answer: (1) The cable specifications should conform to the regulations, the arrangement should be neat, no damage, complete signs, correctness, and clarity;

(2) The fixed bending radius of the cable, the relevant distance and the wiring of the metal sheath of the single-core power cable shall meet the requirements;

(3) The cable terminal and the middle head are not leaking oil, and the installation is firm. The oil pressure of the oil-filled cable and the setting value of the meter should meet the requirements;

(4) Good grounding;

(5) The cable terminal is in correct color, and the metal components such as brackets are complete;

(6) There should be no debris in the cable trench, in the tunnel and on the bridge, and the cover is complete.

75. What are the requirements in the process of measuring the positive sequence impedance of cable lines?

A: The AC resistance of the cable conductor and the phasor of the same three inductive reactance of the cable are called the positive sequence impedance.

The positive sequence impedance of the cable line can be measured directly on the cable tray. Generally, lower voltages are used during measurement. Therefore, step-down transformers are required to perform step-down voltages. The voltage drop device uses star-type wiring, and the capacity is generally 10 kVA or more. For wider voltage regulation range, the AC power supply should be relatively stable during measurement to ensure that the current reaches the specified requirements during measurement. The actual voltmeter reading must be the voltage of the cable end, and the test current is preferably close to the long-term allowable ampacity of the cable. For each meter value, the three tables are read at the same time after closing the current.

76. According to the "Safety Regulations for the Production of Electric Power Industry", what are the necessary conditions for electricians?

Answer: The following conditions must be met:

(1) A medically certified illness that does not interfere with work;

(2) Having the necessary electrical knowledge, according to their duties and the nature of their work, mastering relevant regulations, professional techniques and safe operating techniques, and passing the examination;

(3) Proficiency in emergency methods for electric shock.

77. What should you watch out for during cable transportation?

Answer: (1) In the process of transportation and loading, cables and cable trays should not be damaged. It is forbidden to push the cable tray directly from the vehicle. Cables should not be transported flat and stored flat.

(2) Before transporting or rolling cable trays, it must be ensured that the cable trays are securely fastened, and the oil conduits between the oil-filled cables and the pressurized oil tanks should be fixed and not damaged. The pressure oil tanks should be firm and the pressure indications should meet the requirements.

78, cable fire prevention measures?

Answer: (1) Use flame-retardant cables;

(2) Use fireproof cable brackets;

(3) using fire retardant paint;

(4) Fireproof partition walls and fire dampers are installed at cable tunnels, mezzanine exits, etc.;

(5) Overhead cables should avoid oil pipes and explosion-proof doors. Otherwise, fire protection measures should be taken for local pipes or heat insulation.

79. What aspects should be considered in selecting the section of the power cable?

A: The following aspects should be considered:

(1) Operating current allowed to pass through the cable for a long period of time;

(2) Thermal stability in the event of a short circuit;

(3) The voltage drop on the line must not exceed the allowable operating range.

80, what are the advantages of power cables and overhead lines?

A: (1) Operation is reliable. Because it is installed in a hidden place such as underground, it is damaged by external forces, there is less chance of failure, and the power supply is safe. It will not cause harm to the human body.

(2) The maintenance workload is small and there is no need for frequent inspections;

(3) No need to erect towers;

(4) Helps increase power factor.

Henan sanheng industrial co., LTD., founded in 2000, It is one of the top wire and cable manufacturers in China's wire and cable industry for nearly 20 years. the company has more than 5 production lines.

The production cable can be divided into more than 50 varieties and subdivided into 1000 specifications.All products have passed national certification, such as China compulsory certification, bv certification, Nigerian SONCAP certificate, China national industrial certification, etc. China national industrial production license, etc.It also has the ability to produce products that meet international standards, such as iec, ce, rohs, etc.

If you want to buy wires and cables, you can ask the customer service staff and we will get back to you as soon as possible.

-

600-1000V CU XLPE Power Cable

Conductor:Bare Copper Conductor of Class 1/2 (Solid)

Insulation:XLPE Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request

-

600-1000V AL XLPE Power Cable

3500 V:Bare Aluminum Conductor of Class 1/2 (Solid)

Insulation:XLPE Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request

-

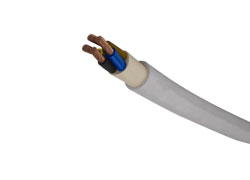

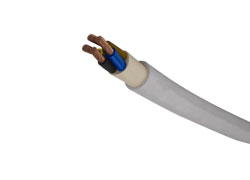

600-1000V Flexible Power Cable

Conductor:Bare Copper Conductor of Class 5 (Flexible)

Insulation:PVC Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request

-

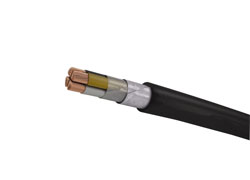

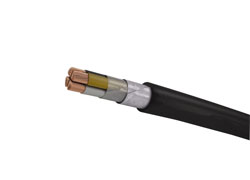

600-1000V SWA Armoured Cable

Conductor:Bare Copper Conductor of Class 1/2 (Solid)

Insulation:XLPE Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request