Chapter 3 Processing and Laying of Cable Pipes

Article 3.0.1 shall not have perforations in the cable ducts, cracks and significant irregularities, the inner wall shall be smooth; metal cable ducts shall not be severely corroded Hard plastic pipes shall not be used in locations where the temperature is too high or too low.

When it is apt to be mechanically damaged and buried directly in a place with a large force, a pipe with sufficient strength should be used.

Article 3.0.2 of the cable tube processing shall meet the following requirements:

First, the nozzle should be free of burrs and sharp edges and corners. The nozzle should be made into a trumpet shape.

Second, after the cable pipe is bent, there shall be no cracks and significant indentations. The degree of bending shall not be greater than 10% of the outside diameter of the pipe. The bending radius of the cable pipe shall not be less than the minimum allowable bending of the cable penetrated. radius.

Third, the metal cable pipe should be coated with anti-corrosion paint or asphalt on the exterior, and the anti-corrosion paint should be applied on the zinc layer of the galvanized pipe.

Article 3.0.3 The ratio of the inner diameter of the cable tube to the outer diameter of the cable shall not be less than 1.5; in addition to the above requirements, the concrete pipe, the clay pipe and the asbestos cement pipe shall have an inner diameter of less than 100 mm.

Article 3.0.4 Each cable tube shall not have more than 3 elbows and not more than 2 right angle bends.

Article 3.0.5 of cable ducts shall comply with the following requirements:

First, the cable tube should be installed firmly; the distance between the cable tube support points should not exceed 3 meters when the design is not specified.

Second, when the straight length of the plastic pipe exceeds 30 meters, expansion joints should be installed.

Article 3.0.6 cable pipe connections shall meet the following requirements:

First, the metal cable pipe connection should be firm, the seal should be good, and the two nozzles should be aligned. The length of the jacketed short tube or threaded fitting should not be less than 2.2 times the outer diameter of the cable tube. Metal cable tubes should not be directly welded.

Second, when the hard plastic tube is socketed or plugged in, the insertion depth should be 1.1 to 1.8 times the inner diameter of the tube. The adhesive surface should be coated with adhesive to secure the seal; when the sleeve is connected, both ends of the sleeve should be sealed. weld.

The position of the cable conduit mouth leading to the equipment in Article 3.0.7 shall be such that it can be easily connected to the equipment without hindering the disassembly, assembly and entry and exit of the equipment. The cable ducts laid side by side should be arranged neatly.

Article 3.0.8 When using the protective steel cable as the grounding wire, the grounding wire shall be welded first; at the threaded pipe joint, the jumper shall be used for welding and then the cable shall be laid.

Article 3.0.9 When the laying of concrete, clay, asbestos cement, etc. cable pipe, the foundation should be solid, smooth, and there should be no subsidence cable pipe laying should meet the following requirements:

First, the buried depth of the cable tube should not be less than 0.7 meters; when laying under the sidewalk, it should not be less than 0.5 meters.

Second, the cable duct should have a drainage gradient of not less than 0.1%.

Third, when the cable pipe is connected, the pipe holes should be aligned and the joints should be tightly closed. No groundwater and mud can penetrate the pipes.

Henan Sanheng Industrial Co., Ltd. , founded in 2000, It is one of the top wire and cable manufacturers in China's wire and cable industry for nearly 20 years. the company has more than 5 production lines.

The production cable can be divided into more than 50 varieties and subdivided into 1000 specifications.All products have passed national certification, such as China compulsory certification, bv certification, Nigerian SONCAP certificate, China national industrial certification, etc. China national industrial production license, etc.It also has the ability to produce products that meet international standards, such as iec, ce, rohs, etc.

If you want to buy wires and cables, you can ask the customer service staff and we will get back to you as soon as possible.

-

PVC Insulated Aluminum Cable

Conductor:Aluminum Conductor of Class 1/2 (Solid)

Insulation:PVC Compound

Insulation Color:Red, Blue, Green, Yellow, Brown, Black, Grey, White, Pink, Orange, Yellow/Green

-

Flexible Flat Cable

Conductor:Stranded Copper Conductor of Class 5/6 (Flexible)

Insulation:PVC Compound

Insulation Color:Red, Blue, Yellow/Green or as request

-

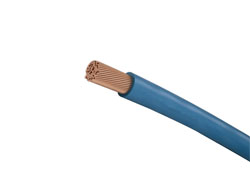

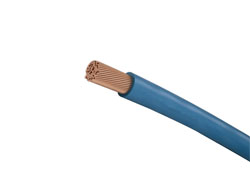

Single Core Flexible Cable

Conductor:Stranded Copper Conductor of Class 5 (Flexible)

Insulation:PVC Compound

Conductor Color:Red, Blue, Green, Yellow, Brown, Black, Grey, White, Pink, Orange, Yellow/Green

-

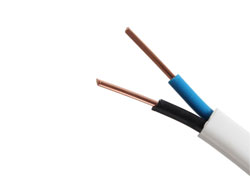

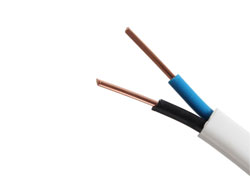

Twin and Earth Cable

Conductor:Class 1/2 copper conductor (solid)

Insulation:PVC Compound

Insulation Color:Red, Blue, Yellow/Green or as request