Chapter IV Preparation and Installation of Cable Brackets

The processing of the 4.0.1 cable holder shall meet the following requirements:

First, the steel should be straight, no obvious distortion. The blanking error should be in the range of 5mm. The incision should have no curling or burrs.

Second, the bracket should be firmly welded without significant deformation. The vertical spacing between the cross braces and the design deviation should not exceed 5 mm.

When it is apt to be mechanically damaged and buried directly in a place with a large force, a pipe with sufficient strength should be used.

Third, metal cable bracket must be treated with anti-corrosion. When it is located in hot, salty, and chemically corrosive areas, special anti-corrosion treatment should be designed.

Article 4.0.2 allows the minimum distance between the layers of the cable support. When the design is not specified, the provisions of Table 4.0.2 can be used. However, the inter-floor spacing should not be less than twice the cable diameter plus 10mm, 35kV and above high-voltage cables should not be less than 2 times the cable diameter plus 50mm.

Table 4.0.2 Allowable minimum distance between layers of cable bracket (mm)

Cable type and laying characteristics Support (hanging) Bridge frame; Control cable 120 200; Power cable 10kV and below (except 6~10kV XLPE insulation) 150~200 250; 6~10kV XLPE insulation 200~250 300; 35kV single-core; 35kV three-core; 110kV and above, each with more than one 300 350; 110kV and above, each with a 250 300; cable laid in the box h +80 h +100. Note: h indicates the height of the enclosure shell.

Article 4.0.3 cable bracket should be installed firmly, horizontal and vertical; brackets and hangers should be fixed according to design requirements. The same level of cross brackets of each bracket shall be on the same level, and the height difference shall not exceed 5mm. The deviation of the support and hanger bracket along the direction of the bridge shall not exceed 10mm.

Cable supports installed in graded cable trenches or on buildings shall have a gradient from the cable trench or building.

The distance between the uppermost floor and the bottom of the cable support to the top of the trench, the floor or the bottom of the trench, and the ground shall not be less than the values in Table 4.0.3 when the design is not specified.

Table 4.0.3 The distance between the uppermost floor and the bottom of the cable supporter to the top of the trench, the floor or the bottom of the trench, and the ground; the laying of the cable tunnel and the cable duct hanger; the uppermost floor to the top of the trench 300 to 350 150 to 200 150 ~200 350 ~ 450; the bottom to the bottom of the trench or the ground 100 ~ 150 50 ~ 100 - 100 ~ 150.

Article 4.0.4 The vertical deviation of the assembled steel structure shaft shall not exceed 2/1000 of its length; the horizontal error of the bracket shall not exceed 2/1000 of its width; the deviation of the diagonal of the shaft shall not be greater than Its diagonal length is 5/1000.

The preparation of the 4.0.5 cable tray shall meet the following requirements:

1. The quality of the support (hanger), connecting parts and accessories of cable ladders (trays) and cable ladders (trays) shall comply with the relevant technical standards in force.

Second, the specifications of the cable ladder (pallet), the span of the hanger, and the type of anti-corrosion should meet the design requirements.

When it is apt to be mechanically damaged and buried directly in a place with a large force, a pipe with sufficient strength should be used.

Section 4.0.6 Ladder (Tray) shall be fixed on each hanger; the bolts on the ladder (pallet) connection plate shall be fastened and the nuts shall be on the outside of the ladder carrier (pallet).

When the aluminum alloy ladder frame is fixed on the steel support hanger, it should be protected against galvanic corrosion.

Article 4.0.7 When the straight-line steel cable tray is more than 30m, aluminum alloy or glass steel cable tray is more than 15m, there shall be expansion joints, and the connection should adopt telescopic connection plate; the expansion of the cable bridge across the expansion joints of the building should be provided with expansion joints. .

Article 4.0.8 The turn radius of cable bridge turn shall not be less than the maximum allowable bend radius of the cable on the bridge.

Section 4.0.9 of the cable support should have a good grounding.

Henan Sanheng Industrial Co., Ltd. , founded in 2000, It is one of the top wire and cable manufacturers in China's wire and cable industry for nearly 20 years. the company has more than 5 production lines.

The production cable can be divided into more than 50 varieties and subdivided into 1000 specifications.All products have passed national certification, such as China compulsory certification, bv certification, Nigerian SONCAP certificate, China national industrial certification, etc. China national industrial production license, etc.It also has the ability to produce products that meet international standards, such as iec, ce, rohs, etc.

If you want to buy wires and cables, you can ask the customer service staff and we will get back to you as soon as possible.

-

PVC Insulated Aluminum Cable

Conductor:Aluminum Conductor of Class 1/2 (Solid)

Insulation:PVC Compound

Insulation Color:Red, Blue, Green, Yellow, Brown, Black, Grey, White, Pink, Orange, Yellow/Green

-

Flexible Flat Cable

Conductor:Stranded Copper Conductor of Class 5/6 (Flexible)

Insulation:PVC Compound

Insulation Color:Red, Blue, Yellow/Green or as request

-

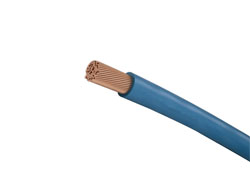

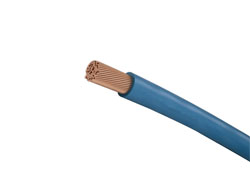

Single Core Flexible Cable

Conductor:Stranded Copper Conductor of Class 5 (Flexible)

Insulation:PVC Compound

Conductor Color:Red, Blue, Green, Yellow, Brown, Black, Grey, White, Pink, Orange, Yellow/Green

-

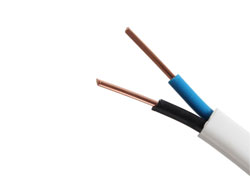

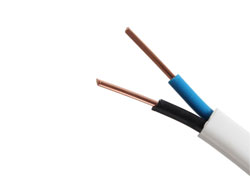

Twin and Earth Cable

Conductor:Class 1/2 copper conductor (solid)

Insulation:PVC Compound

Insulation Color:Red, Blue, Yellow/Green or as request