Summary of cable laying knowledge in power engineering construction

The operation quality, safety and reliability of the power supply system are not only related to the quality of the wire and cable itself, but also related to the construction quality of the cable accessories and lines. The following is a summary of cable laying knowledge in power engineering, and I hope to help you!

First, the laying of the cable

The laying methods of cables include the following types: direct burial laying, pipe laying, shallow groove laying, cable trench laying, cable tunnel laying and overhead laying. Several methods have advantages and disadvantages. Generally speaking, urban development plans must be taken into consideration. Existing buildings The density of the cable, the number of cable runs, and the effect of the surrounding environment. From a technical comparison, the cable tunneling method and the laying of cable trenches are convenient for the construction, maintenance and overhaul of cables. In some developed country cities, public tunnels have been considered when planning and constructing cities. Practice has proved that public tunnels work well, greatly reducing the number of repeated investments and the phenomenon of repeatedly excavating roads. However, the initial investment is huge, and construction materials consume funds. Due to the constraints of various factors, this type of laying is extremely rare. In contrast, direct laying and shallow trough laying are economical laying methods. The buried cable is the most economical and extensive method of electric laying. It is used in places where suburban and vehicle traffic are less frequent. But it is not conducive to the maintenance and overhaul of the cable. Once a cable fault is encountered, even if the tester is used to measure the fault, it is necessary to reopen the cable trench, which is inconvenient. Therefore, the choice of cable laying methods must be based on actual conditions and based on factors such as engineering conditions, environmental characteristics, cable types and quantities, and development perspectives, and should be determined in accordance with the requirements of meeting operational reliability, ease of maintenance, and technical and economical rationality.

Wire and cable knowledge training materials Daquan

Second, the cable selection

The commonly used power cables include oil-impregnated cables, PVC insulated cables, cross-linked polyethylene cables, and the like, which are extended to different types of special cables depending on the occasion. At present, with the continuous improvement of production technology and production technology, cross-linked polyethylene cables have become the most widely used cable products. When selecting cables, they should be selected according to different conditions and conditions to minimize Through various pipe-edge railways, highways and communication cables; when using direct burial and shallow troughs, consideration should be given to the use of steel cables.

Third, the cable cross-sectional area selection

The choice of cable cross-section area relates to the amount of investment, the loss of the line and the voltage quality, and the service life of the cable. If the cross-sectional area is selected to be too small, the voltage quality will be reduced and the line loss will be too large, which will make the initial investment too high. Therefore, according to the load forecasting results, the development plan should be selected and the appropriate cross-sectional area should be selected so that the power cable can meet the core temperature requirements and voltage drop requirements under the maximum operating current, and the thermal stability requirements under the action of the maximum short-circuit current.

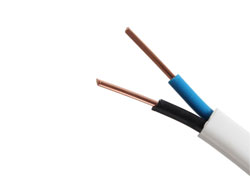

When choosing a power cable for a three-phase four-wire low-voltage power grid, the selection of the zero-line cross-sectional area must also be considered. In a public low-voltage network, the three-phase load balance is difficult to control due to the influence of user factors, so as to improve the voltage quality and reduce the Line loss, the cross-sectional area of the zero line should be the same as the cross-sectional area of the phase line.

Fourth, cable network and cable network automation

With the continuous promotion and use of power cables in distribution networks, distribution networks can be divided into cable networks and overhead networks (including overhead and cable hybrid networks). Therefore, when a cable network is used in a distribution network area network, new technologies and new equipment should be used in accordance with the requirements of distribution automation, and conditions must be considered for automated pilot work. When the conditions are not mature, the auxiliary equipment must be selected. Consider that there is enough room to lay the foundation for an automated solution.

Wire and cable knowledge training materials Daquan

V. Attentions in the construction of power cables

1. Eddy Current Problems Caused by High Current Power Cables

In the construction of power cables, steel brackets are used, steel protection tubes are used, and cable cards and overhead cables are used. Any galvanic (iron) closed loop is formed around the power cable, and eddy currents may form. Especially in high current power cable systems, eddy currents are greater. In the construction of power cables, measures must be taken to prevent the formation of steel (iron) closed loops around the cables to prevent eddy currents from occurring.

2. Mechanical damage caused by turning power cables

As the outer diameter of the power cable is larger, transportation and laying are more difficult, and the power cable has stricter requirements for turning radius. In the construction of the power cable, if the turning angle is too large, the conductor may be mechanically damaged, and the mechanical damage is reduced due to the cable insulation strength until a fault occurs. A cable head failure is found during the construction. When the cable head is manufactured, three cables are used. The length of the head is the same. When the device is connected with the equipment, due to terrain restrictions, the cable head of the middle phase is long and arched, and the root of the cable head is damaged and discharged. After taking measures, in the connection of the device, the length of the connection of the intermediate phase cable head is appropriately shortened so that the three-phase cable heads are not subjected to external forces. Practice has proved that the operation effect is good. It can be seen that during the construction of the cable, the torsion of the cable should be reduced as much as possible. When the cable is turned and the cable is left to stay, the cable is naturally bent to prevent internal mechanical damage.

3, power cable moisture problem

Operation experience shows that most of the faults in the medium and low voltage power cables are faults in the middle and end of the cable, while the faults in the intermediate and terminal faults are mostly caused by poor sealing and moisture intrusion, resulting in a decrease in the dielectric strength, and medium and low voltage power cables. The network adopts the dendritic power supply method, and the number of cable terminal heads is large. Therefore, sealing the cable terminal head and the middle connector plugging is one of the important measures for ensuring the safe and reliable operation of the cable.

4. Earthing problems of medium and low voltage power cables

In the public medium and low-voltage power cable networks, since the three-phase load is not equal, therefore, if a cable with a metal sheath is used, the grounding of the metal sheath must be considered and the non-grounding at any point of the metal sheath must be ensured. The normal induced voltage must not exceed 100V.