Installation of environmentally friendly wire and cable safety precautions

1. Attention must be paid to the completion of the installation of environmental protection wires and cables or the removal of temporary power projects, and electricians must be highly skilled. The installation site requires domestic professional environmental protection wire and cable construction personnel must be familiar with the safety and technical standards, comply with the safety and technical operating procedures, but also check the equipment and protection facilities, but also do a good job electrician maintenance records.

2. Note that all workers who participate in the installation of environmentally friendly wires and cables need to be familiar with the performance and use of electrical safety tools. When carrying out live work, they need to use construction tools with reliable insulated handles to carry out high-voltage cable lines. When testing, professional construction personnel must wear gloves with high-quality insulating layers to prevent the installer from electric shocks and other threats to safety.

Installation of environmentally friendly wire and cable safety precautions

3. Note that when installing or inspecting electrical equipment that is out of power, the following environmental protection cable and cable installation personnel need to take the following safety measures when they encounter installation problems.

1 In the event of a power outage, the construction personnel must power off all equipment that needs to be inspected, and pull at least one distinct disconnect isolation switch.

2 In the event of a power failure, it is necessary to stop the cable load first, and finally pull up the cable disconnect switch and disable the load pull disconnector during the period.

3 When a nearby worker performs a power-off operation, it needs to maintain a safe distance from the charged thing. It is also necessary to check the open position. If there is no connection on the line that can constitute the three-phase load of the point circuit, it needs to be fully discharged.

4 When the common signal mark of the disconnected device is found, it means that the signal of the locking device that allows the entry interval and the indication of the connected voltmeter are no pressure, and can only be used as a reference, and cannot be used as a basis for the device without electricity.

The installation of environmental protection wire and cable is not only to protect the environment from pollution, but also to protect the safety of construction workers and users, so to ensure that the installation of wire and cable work can safely and reliably protect the safety of personal and property, the relevant construction personnel need to be clear and Keep in mind the safety precautions for installing these environmentally-friendly wires and cables. The above content is a summary of the considerations for the installation of domestic professional environmental protection wires and cables. Kexin Cable hopes that the above summary of safety precautions can help Everyone is better and safer to install green wires and cables.

Detailed environmental protection cable production process

Environmental protection cable means that it does not contain heavy metals such as lead, cadmium, hexavalent chromium, and mercury, does not contain brominated flame retardants, and is tested by SGS's recognized testing agencies for environmental performance. It conforms to the European Union's environmental directive (RoSH) and exceeds its specifications. . It does not produce harmful halogen gas, does not generate corrosive gas, and has a small amount of heat when burned. It does not contaminate the soil.

The Japan Electric Cable Industry Association (JCS) standard currently refers to environmentally friendly wire and cable as: EM cable.

EM (ECO-MATERIAL), which means an ecological material with flame retardancy, is characterized by the use of halogen-free and lead-free ecological materials as the insulation and sheathing of electric wires and cables. When cables are burned or discarded, no harmful substances are produced. Wires and cables used as ecological materials do not cause dioxin and lead pollution, and are easy to recycle. At present, the materials used for EM cables are mainly flame-retardant polyethylene and flame-retardant cross-linked polyethylene.

First, the characteristics of environmentally friendly wire and cable

does not contain halogen, does not produce harmful halogen gas when burning;

does not contain lead and other heavy metals;

Low smoke and no corrosive gas when burning;

has a good flame resistance;

material heat-resistant temperature of 75 °C and above;

Reusable for repeated use.

Second, environmental protection cable production process

1, product type

1.1, copper lead-free PVC insulated green cable

1.2, copper core halogen-free low-smoke flame-retardant polyolefin insulation environmental protection cable

1.3. Copper-core halogen-free and low-smoke flame-retardant cross-linked polyolefin insulated environmental protection cable

2, the characteristics of the production process

2.1, inspection of raw materials into the factory

The materials used for the three types of environmental protection cables are lead-free 70°C PVC insulation, thermoplastic low-smoke halogen-free flame-retardant polyolefin insulation, and radiation cross-linked low-smoke halogen-free flame-retardant polyolefin insulation.

Henan Sanheng Cable Co., Ltd , founded in 2000, It is one of the top wire and cable manufacturers in China's wire and cable industry for nearly 20 years. the company has more than 5 production lines.

The production cable can be divided into more than 50 varieties and subdivided into 1000 specifications.All products have passed national certification, such as China compulsory certification, bv certification, Nigerian SONCAP certificate, China national industrial certification, etc. China national industrial production license, etc.It also has the ability to produce products that meet international standards, such as iec, ce, rohs, etc.

If you want to buy wires and cables, you can ask the customer service staff and we will get back to you as soon as possible.

-

PVC Insulated Aluminum Cable

Conductor:Aluminum Conductor of Class 1/2 (Solid)

Insulation:PVC Compound

Insulation Color:Red, Blue, Green, Yellow, Brown, Black, Grey, White, Pink, Orange, Yellow/Green

-

Flexible Flat Cable

Conductor:Stranded Copper Conductor of Class 5/6 (Flexible)

Insulation:PVC Compound

Insulation Color:Red, Blue, Yellow/Green or as request

-

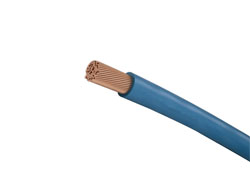

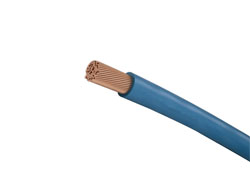

Single Core Flexible Cable

Conductor:Stranded Copper Conductor of Class 5 (Flexible)

Insulation:PVC Compound

Conductor Color:Red, Blue, Green, Yellow, Brown, Black, Grey, White, Pink, Orange, Yellow/Green

-

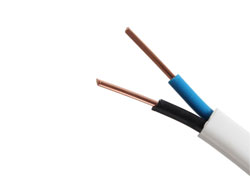

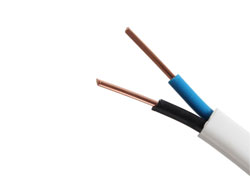

Twin and Earth Cable

Conductor:Class 1/2 copper conductor (solid)

Insulation:PVC Compound

Insulation Color:Red, Blue, Yellow/Green or as request