When the power cable passes a certain load current, it will certainly generate heat. With the increase of the load current, the temperature of the cable surface will be higher. If it is not handled in time, the consequences can be imagined. Such as: polyvinyl chloride (PVC) cable is based on the core temperature of 70 degrees as the upper limit, the surface temperature will be 5 to 10 degrees lower. Therefore, the cable surface temperature below 60 degrees is basically safe. Considering power supply maintenance, the lower the temperature, the better. The cause of the cable heating during operation is as follows:

Wire and cable overheating causes and solutions!

1. Cable conductor resistance does not meet the requirements, causing the cable to generate heat during operation.

2. Improper selection of cables causes the cross-section of the cable used to be too small and overload during operation. After prolonged use, the heating of the cable and unbalanced heat dissipation cause heat generation.

3, the cable is too densely arranged during installation, the ventilation and heat dissipation effect is not good, or the cable is close to other heat sources, which affects the normal heat dissipation of the cable, and may also cause the cable to generate heat during operation.

4, joints manufacturing technology is not good, crimping is not close, resulting in contact resistance at the joint is too large, it will cause the cable to generate heat.

5. The insulation performance between the cables is not good, resulting in a small insulation resistance and heating during operation.

6. The partial sheath of the armored cable is damaged. After the water enters the water, the insulation performance will cause a slow destruction. As a result, the insulation resistance will gradually decrease, which will also cause heating in the cable operation.

Wire and cable overheating causes and solutions!

After the cable generates heat, if the cause is not found and the fault is eliminated in time, the cable will continue to heat up and run, causing thermal insulation breakdown. The occurrence of phase-to-phase short circuit tripping of the cable may cause serious fire hazards.

Plug power cord heating causes and solutions Power cord in the home life can be seen everywhere, the appliance is basically inseparable from the power cord, this little power cord may despise him.

Water heater power cord plug heating is usually caused by poor fit with the socket, while taking into account the normal heating phenomenon, if the plug surface temperature is less than the ambient temperature plus 50 degrees Celsius is normal. Abnormal heat needs to consider replacing the socket or checking the fit of the plug and socket.

1. Poor contact between plug and socket, plus large load power, cause the plug to heat up. Such as electric kettles, irons and so on.

2. The looseness of the thread inside the new plug is caused by the rough production process.

3. The old plugs are used for a long time and the insulation performance is reduced (or the plug is loosened).

How to use the plug cable safely?

The main reason for the electrical heating of the plug wire is that the power consumption of the wire is increased because of the long-term use of electricity in the electrical equipment. In particular, when the multi-functional outlet is connected with several kinds of high-power electrical equipment, the power cord of the outlet must be overloaded, and in that case, it is very easy to cause damage to the electrical cord. Therefore, we must pay attention to reasonable distribution of electricity in life, and we must periodically check the plug wires and sockets to see whether the wires are old and whether the contact between the plug and the socket is bad. Sometimes, because the process of the production department is not fine, the plug of the plug will not be firm, so plugging the power supply will cause poor contact and cause the plug to heat up. At the same time, each household should pay attention to the fact that long-term use of the plug will become old, and the nature of the insulation will also be reduced. It should be replaced in a timely manner. For plugs of high-power electrical appliances, we recommend the use of an increased type of wire core, and it is preferable to use a grounded foot plug. If it is found that the power outlet or the wire plug has a serious heat, which leads to the electrical equipment being burned, it is imperative that you must act with care.

Henan Sanheng Cable Co., Ltd , founded in 2000, It is one of the top wire and cable manufacturers in China's wire and cable industry for nearly 20 years. the company has more than 5 production lines.

The production cable can be divided into more than 50 varieties and subdivided into 1000 specifications.All products have passed national certification, such as China compulsory certification, bv certification, Nigerian SONCAP certificate, China national industrial certification, etc. China national industrial production license, etc.It also has the ability to produce products that meet international standards, such as iec, ce, rohs, etc.

If you want to buy wires and cables, you can ask the customer service staff and we will get back to you as soon as possible.

-

PVC Insulated Aluminum Cable

Conductor:Aluminum Conductor of Class 1/2 (Solid)

Insulation:PVC Compound

Insulation Color:Red, Blue, Green, Yellow, Brown, Black, Grey, White, Pink, Orange, Yellow/Green

-

Flexible Flat Cable

Conductor:Stranded Copper Conductor of Class 5/6 (Flexible)

Insulation:PVC Compound

Insulation Color:Red, Blue, Yellow/Green or as request

-

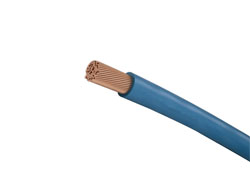

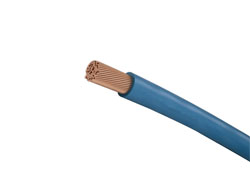

Single Core Flexible Cable

Conductor:Stranded Copper Conductor of Class 5 (Flexible)

Insulation:PVC Compound

Conductor Color:Red, Blue, Green, Yellow, Brown, Black, Grey, White, Pink, Orange, Yellow/Green

-

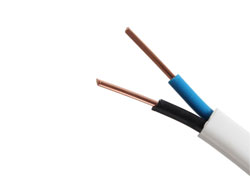

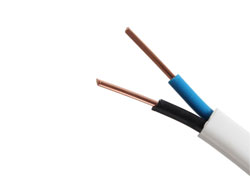

Twin and Earth Cable

Conductor:Class 1/2 copper conductor (solid)

Insulation:PVC Compound

Insulation Color:Red, Blue, Yellow/Green or as request