The industry has been arguing over the characteristics of the network data cable sheath. For example, can the skin meet the flame retardant or low-smoke standards? Does it need to contain high ignition point and flame resistance, but it will release toxic gases in the fire? Halogen? Network cabling professionals, the majority of network users and even between standards organizations in different regions, there are differences. With the arrival of integrated voice, data and image, multimedia broadband, and converged network era, network cabling will be deeper into thousands of households, correctly understanding the composition and characteristics of network data cable sheaths, and building future networks. The work and life of the users and users are very important.

Knowledge of wire and cable outer sheath

For the selection and standards of network data cable sheaths, North American and European standards organizations and manufacturers have been arguing for a long time, like they are using UTP or FTP shielding products. Currently, North America, South America, Asia Pacific, and China use the North American-based cable fire protection standards UL and NEC (National Electrical Code), and some parts of Europe use low-halogen or low-smoke halogen-free green environmental cable standards.

Furnace containing halogen

At present, most of the power and communication cables laid in most parts of the world contain halogens, which emit toxic misty chemicals when burned. In the fire, the halogen-containing cable produces acid gas, which damages the nose, mouth and throat of the worker. The smoke also makes the victim easily lost and unable to escape from the fire.

Recognizing this potential hazard, some European countries have adopted halogen-free cables as the standard for power and communication cables. However, the National Electrical Code clearly states that the communication network must use a Category 5 or Category 6 UTP (Unshielded Twisted Pair) network cable with a halogen-containing cladding. This is because, although the halogen-containing cable has important defects, the halogen itself has strong flame resistance and high ignition point. If the cable is not ignited at all or it is difficult to catch fire, it will not cause combustion, thus emitting toxic fumes. .

In fact, some fires are caused by overheating of the cable itself for a long time. Halogen-free cables are more likely to cause fires because of the low ignition point, and the halogen insulation layer can better prevent the cable from spontaneous combustion. However, if the cable is already in the fire, the smoke it produces can cause life poisoning. These contradictions have been the focus of debate in the industry in the application of halogens.

Nowadays, cable halogen advocates, including the US federal company and Goodrich, occupy a dominant position in technology. Opponents of halogens are expected to be more convinced that NFPA (American Fire Protection Association) amends current standards, ceases to use halogens or allows the use of halogen-free cables in the ventilated spaces of buildings.

Knowledge of wire and cable outer sheath

This is not the first time that halogen-free cable advocates have tried to revise the standard, but it has not been successful so far. The main reason is that the self-igniting layer combustion of the cable in the trunk line makes it difficult for people to carry out regional fire prevention control, which causes fire in the entire building, and the low ignition point is easy to generate fire. Another main reason is that there is no evidence that halogen-free cables can save lives (because there are a lot of other decorations in the house that also contain halogens).

According to the current US Building Act, the only legally installed halogen-free cable is to place the cable in a metal conduit, which doubles the cost of the entire wiring system. As a result, most European countries, including France, Italy and the United Kingdom, have switched to halogenated cables. Among the communication cables in Europe, halogen-free cables currently account for about 25% of the total, while in North America and most parts of the world, there are more than 98% of the market for halogen cables. The wiring manufacturer Avaya has launched a full range of data cable solutions for different standards and users in different regions to meet the needs of different users.

Halogen free

Halogen-free features are: low ignition point, easy to burn but low toxicity. The current international standards related to cables focus on three issues: fire resistance (speed of cable burning), density of smoke (how much visible smoke is produced), and toxicity (how much damage is caused to the human body). The US fire protection standard only covers the first two problems, but it is more widely used and stricter. To meet the US standards, halogen must be added to the cable insulation polymer. The PVC cable contains chlorine, and FEP (Teflon). The Teflon polytetrafluoroethylene cable contains fluorine.

FEP is highly resistant to fire and can withstand temperatures up to 800 °C before it breaks down. It is several times higher than the typical halogen-free cable that can withstand temperatures up to 150 °C. FEP is also an efficient insulator. Therefore, FEP is very suitable for making cables for transmitting high-speed data. It is a key factor in the widespread use of Super Category 5 UTP in ventilation. In high-rise shafts and other ventilated areas, FEP cables have largely replaced PVC cables. In some countries in Europe, the standards are different. In order to comply with strict anti-toxic specifications, cable manufacturers do not use halogens and instead metal is added to the polyethylene and polyene cable insulation. When heated, this cable emits only visible vapors that are less toxic. However, this halogen-free cable is not as fire-resistant as a halogen-containing cable, and its insulating layer burns quickly. Therefore, halogen-free cables cannot meet strict US fire protection standards. To achieve fire protection and ventilation level fire protection requirements, excessive metal hydroxides have to be added, which affects cable performance and technical requirements.

Cable toxicity

When the PVC cable burns, it emits hydrogen fluoride and dioxide gas, which are identified by Greenpeace as "scientifically known, toxic synthetic chemicals." When the FEP cable burns, it releases a colorless, odorless hydrogen fluoride that is more toxic than hydrogen chloride. Tests have shown that there is another dangerous gas in the FEP smoke. This supertoxin has never been correctly recognized by humans, and its research has stopped. However, some people think that this supertoxin is only an experimental product, and it does not exist in reality.

Henan Sanheng Cable Co., Ltd , founded in 2000, It is one of the top wire and cable manufacturers in China's wire and cable industry for nearly 20 years. the company has more than 5 production lines.

The production cable can be divided into more than 50 varieties and subdivided into 1000 specifications.All products have passed national certification, such as China compulsory certification, bv certification, Nigerian SONCAP certificate, China national industrial certification, etc. China national industrial production license, etc.It also has the ability to produce products that meet international standards, such as iec, ce, rohs, etc.

If you want to buy wires and cables, you can ask the customer service staff and we will get back to you as soon as possible.

-

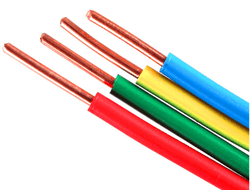

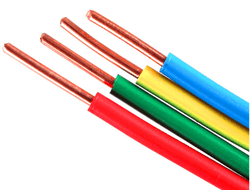

600 1000V CU XLPE Power Cable

Conductor:Bare Copper Conductor of Class 1/2 (Solid)

Insulation:XLPE Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request

-

600-1000V AL XLPE Power Cable

3500 V:Bare Aluminum Conductor of Class 1/2 (Solid)

Insulation:XLPE Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request

-

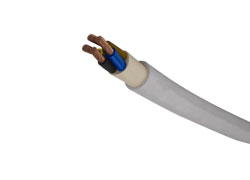

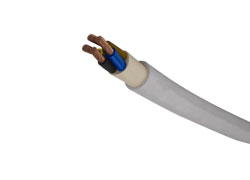

600-1000V Flexible Power Cable

Conductor:Bare Copper Conductor of Class 5 (Flexible)

Insulation:PVC Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request

-

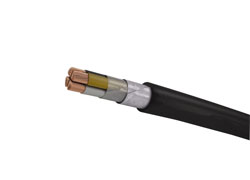

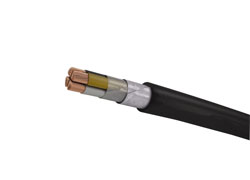

600-1000V SWA Armoured Cable

Conductor:Bare Copper Conductor of Class 1/2 (Solid)

Insulation:XLPE Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request