Low-smoke, halogen-free cable refers to an environmentally friendly cable that is made of a rubber material that does not contain halogens (F, Cl, Br, I, At), and does not contain lead, cadmium, chrome, mercury, etc., and does not emit toxic fumes when burned. The following is the evolution and rise of low-smoke halogen-free flame retardant cable materials organized by cable recruitment network. Welcome to know!

1. Halogen-free and halogen-free debate

Halogen-containing (especially bromine) flame retardant polymer systems have an absolute dominance in the flame retardant polymer market since the mid-1980s due to their outstanding flame retardant effect. Polyvinyl chloride (PVC (5030, -35.00, -0.69%)) in the wire and cable industry is one of them, and it still plays a major role in the sheath and insulation.

The evolution and rise of low-smoke halogen-free flame retardant cable materials

With the advancement of society and the rapid development of science and technology, the inherent weakness of PVC (a large amount of smoke released during combustion, severe corrosive gases and toxic gases) has been invented.

Since then, the evaluation and search for alternatives to PVC materials has become the focus of debate. As early as 1986, Europe first discovered that PBDEs contained in combustion products, tetrabromobisbenzodioxane and tetrabromobisbenzofuran were carcinogens.

Until 2001, the United States discovered pentabromodiphenyl ether in succession. The bioaccumulation of decabromodiphenyl ether in wild falcon eggs was 400 times higher than that of domestic falcon eggs. The initiative to reject the production and use of brominated flame retardants was again initiated.

2. The formation of two long-standing concepts of fire safety

Halogen-free flame retardant systems have gradually entered Europe in the past 15 years and have been accepted as part of cable manufacturing technology. This is not the case in the United States, which is generally limited to products that are sold back to Europe. Europe and the United States have completely opposite views based on different national conditions and backgrounds: the concept of American circulation believes that the root cause of disasters is the generation of carbon monoxide (CO) gas and the subsequent conversion of CO to CO2 during the "flashover" process. The heat is released.

Therefore, if there are some ways to control the heat release of the process, the fire hazard can be reduced. The European tradition has been convinced that the severity of the disaster depends on the success rate of people leaving the fire scene. The irritancy and toxicity of smoke are the main factors that restrict the escape from the fire scene.

Therefore, priority should be given to the smoke, poison, and corrosion generated during combustion. In other words, it is imperative to completely abandon the production and use of halogen substances. The above dispute has spread to the entire industry. During the period of 1997.2.-1999.9, the 12 countries of Europe (particularly participating in Japan) held a special discussion on the search for halogen substitutes in the electrical and electronic products (including printed circuit boards, wire and cable, device packaging, coupling parts, etc.).

Actively looking for alternatives to halogen-containing flame retardants has become a top priority in the industry.

Progress in the cable industry

The development of the wire and cable industry is particularly prominent. There are currently a large number of suppliers of wire and cable materials in the world. Most of these manufacturers are currently engaged in the development and production of halogen-free materials. For example: DuPont, Alpha Gary, BASF, Bayer, Borealis, Exxon, Hoechst and Shell Chemicals. There are different types of halogen-free cable products available on the market for different applications (architectural, communication, transportation, railway, etc.).

It should be noted that with the development of the cable industry, in addition to power cables, the mains (220/240 volt) wiring cable, telephone cable and data cable in the building have made great progress.

The evolution and rise of low-smoke halogen-free flame retardant cable materials

To date, more than half of the power cable (< 1 kV) and 220/240 volt mains cable materials are still PVC cable materials. Generally, the building mains wiring cable and telephone cable are sheath (PVC) + insulation (PVC); data cable: sheath (PVC) + insulation (medium or high density PE).

There are trends that LSZH will gradually become the first choice for these cable materials in important situations. For example, since the terrible fire accident in the Royal London Underground Station, the relevant departments have already specified that LSZH cable materials that meet the technical specifications must be used in public.

The emergence of modern computer networks has led to the rapid development of computer local area networks (LANs), which in turn has led to an increasing demand for interconnected data transmission cables. It is generally estimated that each computer requires an average of 100 meters of LAN cable. Because the electrical performance of the data cable is much better than the telephone cable.

Therefore, with further development, the LAN cable will definitely enter the internal telephone system. Facing the US-based objection and considering the future development prospects, and further promoting the cable material industry mainly based on halogen-free polyolefin cable materials, the FROCC (Fire Retardant Olefinic Cable Compounds) Association was established in Europe in 2001.

Henan Sanheng Cable Co., Ltd , founded in 2000, It is one of the top wire and cable manufacturers in China's wire and cable industry for nearly 20 years. the company has more than 5 production lines.

The production cable can be divided into more than 50 varieties and subdivided into 1000 specifications.All products have passed national certification, such as China compulsory certification, bv certification, Nigerian SONCAP certificate, China national industrial certification, etc. China national industrial production license, etc.It also has the ability to produce products that meet international standards, such as iec, ce, rohs, etc.

If you want to buy wires and cables, you can ask the customer service staff and we will get back to you as soon as possible.

-

600 1000V CU XLPE Power Cable

Conductor:Bare Copper Conductor of Class 1/2 (Solid)

Insulation:XLPE Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request

-

600-1000V AL XLPE Power Cable

3500 V:Bare Aluminum Conductor of Class 1/2 (Solid)

Insulation:XLPE Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request

-

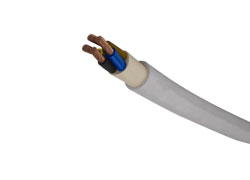

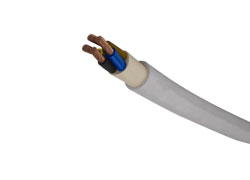

600-1000V Flexible Power Cable

Conductor:Bare Copper Conductor of Class 5 (Flexible)

Insulation:PVC Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request

-

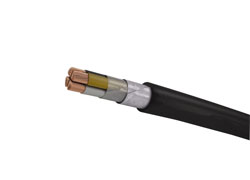

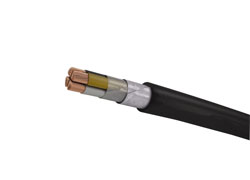

600-1000V SWA Armoured Cable

Conductor:Bare Copper Conductor of Class 1/2 (Solid)

Insulation:XLPE Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request