Henan Sanheng Cable Co., Ltd , founded in 2000.

1. Why should a return line installed along the cable be installed in the grounding mode of the single-core cable sheath at one end?

In the cable line grounded at one end of the metal sheath, in order to ensure that the induced voltage in the sheath does not exceed the allowable standard, a conductor laid along the cable line in parallel must be installed, and both ends of the conductor are grounded. This conductor is called a return line. . When a single-phase ground fault occurs, the ground short-circuit current can flow back to the system center point through the return line, and the magnetic flux generated by the ground current through the return line cancels the magnetic flux generated by the ground current of a part of the cable lead, thereby reducing The induced voltage of the sheath in the event of a short circuit fault.

Cable related tips.

2. Can a cable project be divided into several projects?

(1) Construction site transportation: including loading and unloading, transportation and empty return of engineering materials from warehouse to construction site.

(2) Local engineering: including road excavation, tunneling, and channel construction.

(3) Laying work: including laying, intermediate head making, shovel cover, buried pipe, school tide, traction head production, etc.

(4) Both ends of the project: including the production and installation of the branch, the suspension bridge and its foundation, the production of the terminal head, the installation of the oil pressure and signal device, and the electrical performance test of the name.

(5) Stopping works: including the production of oil-filled cable plugs, the installation of fuel tanks, automatic drainage and signal devices.

(6) Grounding engineering: including insulation joints, transposition boxes, protectors, grounding box installation, etc.

3. What inspections should be carried out on the acceptance of cable lines?

(1) Cable specifications should meet the requirements, the arrangement should be neat, no damage, the signs are complete, correct and clear;

(2) The fixed bending radius of the cable, the relevant distance and the wiring of the metal sheath of the single-core power cable shall meet the requirements;

(3) The cable terminal and the middle head are not leaking oil, and the installation is firm. The oil pressure of the oil-filled cable and the setting value of the meter should meet the requirements;

(4) Good grounding;

(5) The color of the cable terminal is correct, and the metal parts such as the bracket are completely painted;

(6) There should be no debris in the cable trench, tunnel and bridge, and the cover is complete.

4. What are the requirements for the positive sequence impedance measurement of cable lines?

The phasor of the AC resistance of the cable conductor and the same inductive reactance of the cable three is called the positive sequence impedance.

The positive sequence impedance of the cable line can be directly measured on the cable reel. Generally, a lower voltage is used for the measurement. Therefore, the step-down transformer is required for step-down. The buck is a star connection, and the capacity is generally 10 kVA or more. A wide range of voltage regulation, the AC power supply should be relatively stable during measurement to ensure that the current meets the specified requirements during the measurement. The actual voltmeter reading value must be the voltage at the cable end. The test current is preferably close to the long-term allowable current capacity of the cable. When the values of the meters are counted, the values of the three tables are simultaneously read after the current is closed.

5. According to the “Electricity Production Safety Regulations”, what are the conditions that electrical workers must have?

(1) A medical condition that is identified by a doctor and that does not interfere with work;

(2) Have the necessary electrical knowledge, master relevant regulations, professional techniques and safe operation techniques according to their duties and work nature, and pass the examination;

(3) Proficiency in electric shock emergency methods.

6. What should be paid attention to during the transportation and loading and unloading process of the cable?

(1) During the transportation loading and unloading process, the cable and cable reel should not be damaged. It is strictly forbidden to push the cable reel directly from the vehicle. The cable should not be transported flat and stored flat.

(2) Before transporting or rolling the cable tray, the cable tray must be secure. The cable should be tightly tightened. The oil pipe between the oil-filled cable and the pressure tank should be fixed. It should not be damaged. The pressure tank should be firm and the pressure indication should meet the requirements.

7. What are the measures for cable fire prevention?

(1) using a flame retardant cable;

(2) using fireproof cable brackets;

(3) using fireproof coatings;

(4) Fireproof partition walls and fireproof baffles are installed at cable tunnels, mezzanine exits, etc.;

(5) Overhead cables should be avoided from oil pipelines and explosion-proof doors. Otherwise, local pipe penetration or fire prevention measures should be taken.

8. What are the considerations for selecting the cross section of the power cable?

(1) The working current that the cable is allowed to pass for a long time;

(2) Thermal stability once short-circuited;

(3) The voltage drop across the line must not exceed the allowable operating range.

9. What are the advantages of power cables and overhead lines?

(1) It is reliable in operation. Because it is installed in a hidden place such as underground, it is less damaged by external forces, and there are fewer chances of failure. The power supply is safe and will not cause harm to the person;

(2) The maintenance workload is small and does not require frequent inspections;

(3) There is no need to set up a tower;

(4) Help to improve the power factor.

Henan Sanheng Cable Co., Ltd , founded in 2000, It is one of the top wire and cable manufacturers in China's wire and cable industry for nearly 20 years. the company has more than 5 production lines.

The production cable can be divided into more than 50 varieties and subdivided into 1000 specifications.All products have passed national certification, such as China compulsory certification, bv certification, Nigerian SONCAP certificate, China national industrial certification, etc. China national industrial production license, etc.It also has the ability to produce products that meet international standards, such as iec, ce, rohs, etc.

If you want to buy wires and cables, you can ask the customer service staff and we will get back to you as soon as possible.

-

600 1000V CU XLPE Power Cable

Conductor:Bare Copper Conductor of Class 1/2 (Solid)

Insulation:XLPE Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request

-

600-1000V AL XLPE Power Cable

3500 V:Bare Aluminum Conductor of Class 1/2 (Solid)

Insulation:XLPE Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request

-

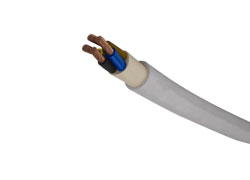

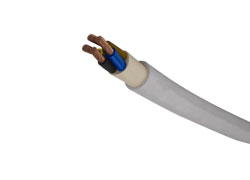

600-1000V Flexible Power Cable

Conductor:Bare Copper Conductor of Class 5 (Flexible)

Insulation:PVC Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request

-

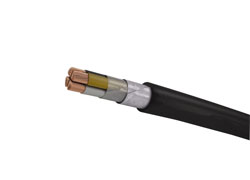

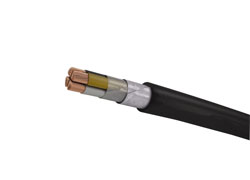

600-1000V SWA Armoured Cable

Conductor:Bare Copper Conductor of Class 1/2 (Solid)

Insulation:XLPE Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request