Henan Sanheng Cable Co., Ltd , founded in 2000.

The vigorous development of urbanization has made urban space more and more tense. Because of the demand of industrial enterprises, cable entry has become an inevitable choice. However, in recent years, external insulation damage and installation quality have caused cable insulation breakdown and even explosion, which have become major accidents in the power grid. In general, there are several reasons for cable insulation breakdown.

Analysis and treatment of cable insulation breakdown

One is mechanical damage.

The excavator accidentally injured the cable due to heavy objects, and the cable was bent too much during the laying to damage the insulation. The cable was severely squeezed during shipment to damage the insulation and protective layer. Both cause damage to the insulation and even break the cable. To avoid mechanical damage to the cable, an overhead cable can be used. If the cable is laid along the wall, the ground should be clearly marked, and the soil should be taken near the cable line in time.

Second, improper construction.

Due to poor construction methods and poor quality of materials used, the cable head and the weak link in the middle are broken, resulting in breakdown of the insulation. To prevent this phenomenon, the installation quality of the cable head should be improved. During the manufacture and installation of the cable head, the insulation bag should be tight and no gap should be present. Before the epoxy resin and quartz powder, strict drying treatment should be carried out to prevent bubbles and moisture from entering the cable head and to strengthen the insulation treatment of the edge of the lead sheath.

Analysis and treatment of cable insulation breakdown

Third, the insulation is damp.

Due to the poor construction process of the cable head, moisture is intruded into the interior of the cable, or the inner protective layer of the cable is broken to allow moisture to enter. The lead-clad cable is laid near the source and is fatigue-cracked due to long-term vibration. The cable sheath is corroded to create voids. Due to poor manufacturing quality, there are small holes or cracks in the lead pack. In these cases, the maintenance of the outer layer of the cable should be strengthened, and a layer of asphalt should be applied to the outer sheath regularly.

The fourth is overvoltage.

The insulation layer is broken down due to atmospheric overvoltage or internal overvoltage, especially if the internal overvoltage of the system causes multiple cables to be broken at the same time. In this regard, lightning arresters should be installed to improve the technical level of automatic system protection.

The fifth is insulation aging.

In the long-term operation of the cable, the electrical and mechanical properties of the insulating material are deteriorated due to poor heat dissipation or overload, and the insulating layer becomes brittle or broken. If this is the case, the cable should be tested for preventive withstand voltage on a periodic basis. It is found that the cable insulation reduction cannot meet the requirements for safe operation, and a new cable should be replaced.

Henan Sanheng Cable Co., Ltd , founded in 2000, It is one of the top wire and cable manufacturers in China's wire and cable industry for nearly 20 years. the company has more than 5 production lines.

The production cable can be divided into more than 50 varieties and subdivided into 1000 specifications.All products have passed national certification, such as China compulsory certification, bv certification, Nigerian SONCAP certificate, China national industrial certification, etc. China national industrial production license, etc.It also has the ability to produce products that meet international standards, such as iec, ce, rohs, etc.

If you want to buy wires and cables, you can ask the customer service staff and we will get back to you as soon as possible.

-

600 1000V CU XLPE Power Cable

Conductor:Bare Copper Conductor of Class 1/2 (Solid)

Insulation:XLPE Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request

-

600-1000V AL XLPE Power Cable

3500 V:Bare Aluminum Conductor of Class 1/2 (Solid)

Insulation:XLPE Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request

-

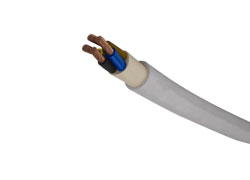

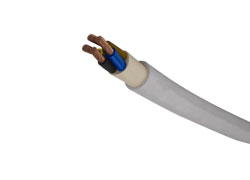

600-1000V Flexible Power Cable

Conductor:Bare Copper Conductor of Class 5 (Flexible)

Insulation:PVC Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request

-

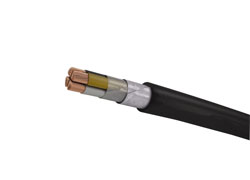

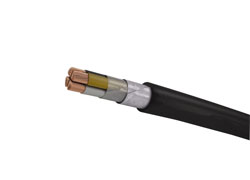

600-1000V SWA Armoured Cable

Conductor:Bare Copper Conductor of Class 1/2 (Solid)

Insulation:XLPE Compound

Insulation Color:Red, Blue, Grey, Yellow/Green or as request